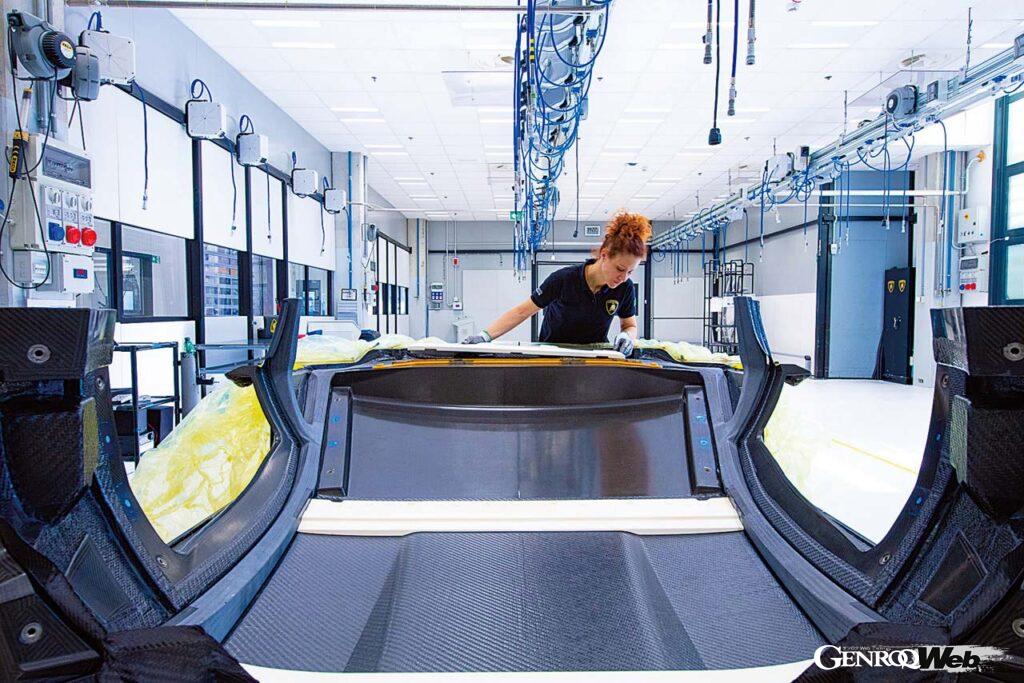

Lamborghini Factory

In-house carbon monocoque production since 2011

The bathtub and roof sections of the monocoque are made separately and then joined together with adhesive, with as much as 140m of adhesive used to make one Revuelto.

Carbon fiber is an essential part of the engineering of modern super sports cars. The use of this lightweight, highly rigid material for the frame, which is the core of the body, was originally a technology used in Formula cars. Once its usefulness was recognized, carbon fiber soon began to be used in various parts of commercial super sports cars, including the frame.

Lamborghini began using carbon fiber (CFRP) for the center monocoque of the Aventador, which was released in 2011, and at the same time built a dedicated factory in Sant’Agata to manufacture the carbon fiber in-house. As you know, manufacturing carbon fiber parts is extremely time-consuming and labor-intensive, and requires large-scale equipment such as ovens for heating. Outsourcing would have been an option, but it is natural that manufacturing in-house gives greater flexibility. It is likely that the decision to build a new factory was made in anticipation of future demand growth.

All large carbon parts are made by hand

The carbon prototype is enclosed in red vinyl and then vacuumed together with the mold. You can see the oven in the back where the carbon is baked. Since it heats the monocoque, it needs to be quite large.

During our visit, we were given the opportunity to experience the actual process of making carbon fiber parts. This involves creating an object based on Revuelto’s designs. The process involves attaching a carbon fiber sheet to the inside of a female mold, then sealing the entire thing in plastic. The air is then removed from the inside to create a vacuum, which allows the carbon fiber sheet to adhere tightly to the female mold. Once it has hardened completely in an oven, it is removed from the mold and completed.

After this experience, I was given a tour of the manufacturing process for Revuelto’s carbon monocoque, and it was made using exactly the same method. Carbon sheets are attached by hand to the large monocoque female mold, then placed in a large plastic bag, sealed, and the air is removed. This is then heated in a large oven at 130°C and 2.5 to 6 bar of pressure. It’s amazing that so much of this is done by hand. The Revuelto monocoque tab is quite large, but several staff members patiently attach the carbon sheets, then place it in a plastic bag and remove the air. The scene looks more like a workshop making arts and crafts than a workshop making cars.

Of course, the product is not finished once it has been baked in the oven. Many staff members check over 300 areas for scratches, distortions, and air bubbles using visual inspection, laser scanning, ultrasound, and other methods, and only if they pass the inspection are they ready to be used as a product.

Carbon recycling technology also developed

The baked carbon monocoque undergoes various checks and is then polished.

After inspection, the carbon monocoque is piled up in a corner of the factory, where the aluminum subframe is bolted on and the engine and body panels are attached.

Lamborghini generally manufactures complex shapes in-house, and the Huracan STO’s cofango (one-piece bonnet), rear fenders, and rear bonnet were all made here. On the other hand, the RTM (resin transfer molding) process for the Revuelto’s body sides is outsourced. Recently, Lamborghini has also been focusing on recycling, using leftover carbon sheets after cutting at an education center, and has also established the technology to separate used carbon fiber into fiber and resin for reuse.

This was my first time seeing a carbon monocoque in action, and I realized that it takes a lot more time and effort than I had imagined. It makes sense why it’s only used in small-scale production cars like the Revuelto, and why it’s so expensive. However, Lamborghini holds many patents for its carbon fiber manufacturing methods, so it may eventually develop a technology that allows it to mass-produce the same quality at a lower cost, making it possible to use carbon composites on all of its models.

A stunningly modern assembly line

The factory is spacious and comfortable. There are no conveyor belts or other equipment, so it is very neat and tidy.

A small-batch supercar manufacturer might have an image of a cottage-based, handicraft-based industry, but Lamborghini’s assembly site is surprisingly modernized. However, many parts are still done by hand. It’s impressive how they maximize the benefits of both. As I mentioned earlier, Lamborghini currently sells over 10,000 cars a year. All of them are produced at the factory in Sant’Agata, in the Bologna region of Italy. This is, of course, where Ferruccio Lamborghini founded the company in 1963, and the fact that they stubbornly maintain production in that location shows that Ferruccio’s spirit is still being passed down to this day.

The factory has continued to expand as production has increased. The carbon fiber manufacturing factory introduced in the previous section has been in operation since 2011, and a new paint factory was built in 2019. Everything at Lamborghini, including engine production and assembly, is completed here in Sant’Agata.

The body moves along the line on a self-propelled unit.

When you think of a small-batch supercar manufacturer, you might imagine a cottage-based, handicraft-based manufacturing environment, but Lamborghini’s assembly plant is surprisingly modernized. However, many parts are still done by hand. It’s impressive how they make the most of the benefits of both.

The engine and body assembly department is an extremely spacious space, and what’s striking is how clean it is. Bodies move along the line automatically on self-propelled units. Work hours are set for each department, and staff complete their assigned tasks within the allotted time, after which the body moves to the next location on its own. Everything is done efficiently and systematically, and there are large displays scattered throughout the factory that digitally display the remaining time for work. This method was introduced with the production of the Huracan, and it has apparently greatly improved work efficiency.

In places where small parts are handled, such as engine assembly lines, staff wear devices similar to smartwatches on their hands. The devices display the parts needed for the next job and record each time a necessary part is taken from a stock shelf. Staff can then place the selected part in a designated location, preventing forgetting to take it or having duplicates. This is a system that places emphasis on reducing the burden and mistakes of workers and ensuring efficient work.

The engine is assembled by hand

Many aspects of engine assembly are made possible by human skill. The Revuelto’s V12 engine is the equivalent of nine Nissan vehicles. After inspecting the interior leather for scratches, the most efficient pattern is calculated and the leather is cut accordingly. All stitching is done by hand.

That said, there is still a lot of work that is done by hand. In particular, many parts of engine assembly are done by hand by skilled workers. This time, we were given a thorough tour of the assembly process of the cylinder block and cylinder head of the Revuelto V12 engine. First, the cylinder head is placed on the block, and grease is applied by hand to the ten bolts, each about 20cm long, which are then inserted into place by hand. They are then tightened with a hand tool (Makita) to a torque of 30Nm. After that, a robot tightens them all in one go to a torque of 135-160Nm. By doing the delicate initial steps by hand and then letting the robot take over the rest, the advantages of each process are utilized.

Speaking of hand-made, the leatherwork for the interior is also almost entirely done by hand. The dyed leather is first checked for scratches, and after cutting, it is sewn and attached to the panels. Of these, only the cutting is mechanized; everything else is done by hand. Although mechanization and digitization are progressing in many aspects, this has allowed the staff to concentrate more on the complex manual work.

Full-scale production of the Temerario will begin in 2025, with the first BEV model scheduled to be produced at this factory in 2030. It is expected that digitalization will continue to advance in line with this, but digital technology will remain focused on supporting the handiwork of skilled staff. It is ultimately humans who assemble Lamborghinis. This philosophy has continued since Ferruccio’s time, and will remain unchanged into the future.

REPORT/Gensuke NAGATA

PHOTO/LAMBORGHINI SpA, GENROQ

MAGAZINE/ GENROQ February 2025 issue