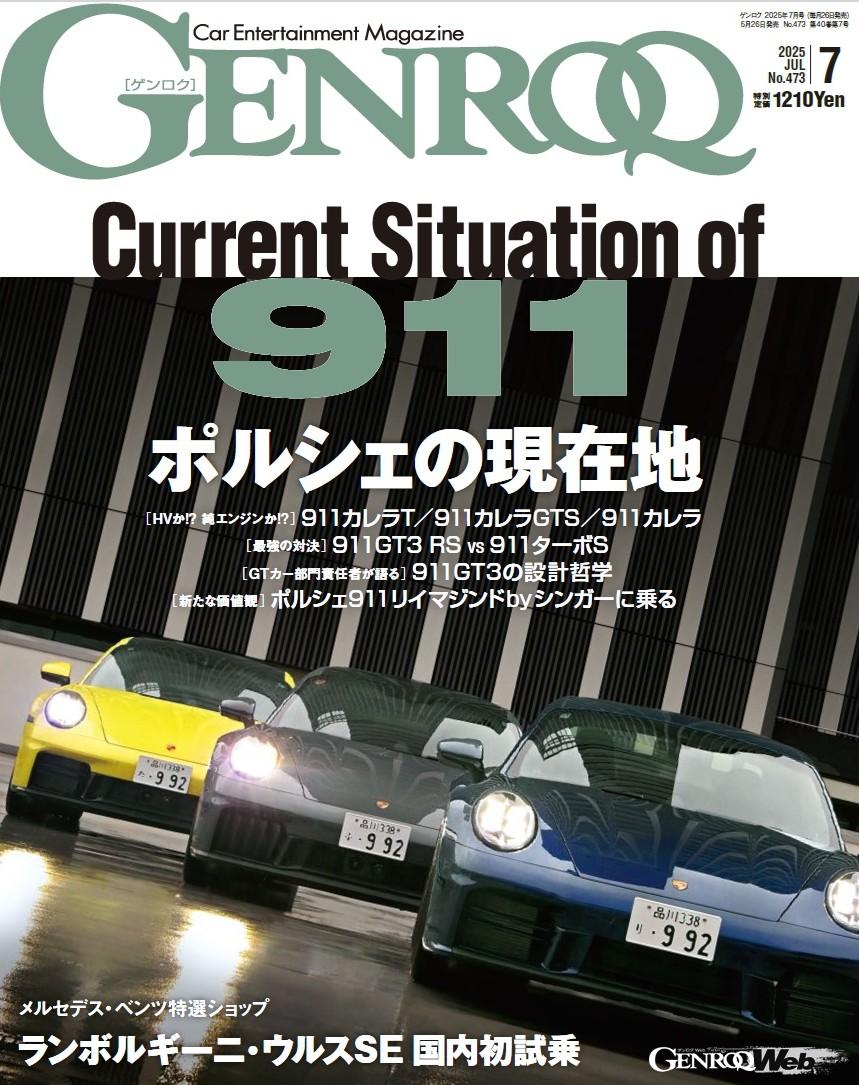

McLaren MP4/1 & McLaren W1

An essential material for super sports

F1-derived carbon fiber technology is an essential material in the construction of McLaren Automotive’s super sports cars.

McLaren has been competing in Formula 1 for over 60 years. Innovative technologies born from motorsport have been incorporated into McLaren Automotive’s super sports cars in various forms, and with its advanced carbon fiber technology, McLaren continues to be a global leader in the field of materials science.

Today, carbon fiber is an essential component in super sports cars that deliver the highest performance on both the circuit and public roads. Since the McLaren F1, the first road-going super sports car, all McLaren production models have been developed based on a chassis made from this composite material.

Carbon fiber’s light weight and high rigidity not only deliver performance and thrilling driving dynamics, but also offer the combined benefits of ride comfort, efficiency, safety and durability on a par with luxury saloons. Furthermore, its incredible packaging solutions allow designers to create super sports cars with beautiful exteriors and aerodynamic performance.

McLaren Automotive CEO Michael Reiters commented on the importance of carbon fibre:

“Carbon fibre is an essential part of the McLaren story and is at the core of our DNA. It not only enables us to build an ultra-lightweight super sports car with the highest dynamic characteristics, but it is also an area where we can continue to explore the technology further.”

McLaren MP4/1 (1981)

The MP4/1, introduced in the 1981 season, was the first car in F1 to feature a carbon fiber monocoque, which quickly became popular in F1.

The McLaren MP4/1, the first F1 car to feature a full carbon fibre monocoque chassis, revolutionised Grand Prix racing. Its lightweight, highly rigid structure significantly improved safety and performance. Designed by John Barnard, this pioneering chassis accelerated the widespread use of carbon fibre in motorsport and forever changed F1 car design.

In the 1981 season, McLaren introduced the MP4/1 at the fourth race, the San Marino Grand Prix, and John Watson brought McLaren its first victory in three years at the ninth race, the British Grand Prix. Furthermore, at the thirteenth race, the Italian Grand Prix, the superiority of carbon fiber was also proven from a safety perspective, when Watson survived an accident at a speed of 140 km/h without injury. This accident was a major turning point that convinced F1 officials that carbon fiber chassis were an essential technology for F1.

McLaren F1 (1993)

The McLaren F1 introduced a carbon fiber monocoque chassis and body to the road-going super sports car, delivering performance that dwarfed its contemporaries.

Among the epoch-making features of the McLaren F1, the most notable is its carbon fibre monocoque chassis and full carbon fibre body, which helped the car to pioneer the use of carbon fibre in road cars, weighing just 1,140kg.

The McLaren F1’s 6.1-liter V12 engine produced a maximum output of 627 PS, and its lightweight carbon fiber construction gave it unrivaled performance. The carbon fiber monocoque was designed using cutting-edge computer analysis at the time, achieving an unprecedented power-to-weight ratio for a road car.

The McLaren F1 GTR then took overall victory at the 1995 24 Hours of Le Mans, completing a full cycle of carbon fiber technology, from the track to the road and back again.

McLaren 12C (2011)

The 12C was McLaren Automotive’s first production road car, introducing the lightweight, high-rigidity single-piece carbon fiber MonoCell.

The McLaren 12C was the first road car produced by McLaren Automotive at the McLaren Production Centre (MPC). The 12C featured MonoCell, a single-piece carbon fiber tub, the world’s first mass-produced full carbon fiber tub, achieving unprecedented rigidity and lightness for a road car at the time.

The MonoCell was one of many innovative new technologies adopted for the 12C, but for McLaren Automotive it was an important “core” in building the DNA of a modern super sports car. Compared to the aluminum chassis that were common at the time, the tub itself was incredibly light at 75 kg, and had such excellent torsional rigidity that no additional reinforcement was required for the chassis itself when the 12C was converted into an open-top model.

McLaren P1 (2013)

The “P1” was developed as part of the Ultimate Series, following the McLaren F1, and uses the number “1” in its name.

In 2013, just two years after the launch of the 12C, McLaren Automotive once again revolutionised carbon fibre technology with the world premiere of the McLaren P1.

The P1 is the second car in the Ultimate Series to feature the number “1” in its name, following the McLaren F1. It features a full carbon fiber body structure, incorporating the roof and lower structure, roof snorkel, engine air intake, battery and power electronics housing into a structure called the “Monocage.”

This makes it possible to deliver high performance as a truly lightweight super sports bike without compromising on the weight increase caused by the hybrid system.

McLaren 720S (2017)

The McLaren 720S introduced a new carbon fiber monocoque chassis, the Monocage II. The photo shows the successor model, the 750S.

The McLaren 720S introduced the Monocage II carbon fiber monocoque chassis, also used in the current 750S. Monocage II offers improved rigidity and reduced weight. This lightweight structure makes up the entire passenger cell, and is further reduced in weight by combining a carbon fiber tub and a carbon fiber upper structure.

The Monocage II’s incredibly slim roof pillars provide excellent visibility through the windscreen, and combined with the B-pillars positioned behind the cab-forward cockpit, create exceptional interior space. The Monocage II’s sills also slope downward toward the passenger’s feet, improving ingress and egress with the adoption of dihedral doors.

In 2018, the McLaren Composites Technology Centre (MCTC) opened in Sheffield, UK. Established as a partnership between McLaren Automotive, the University of Sheffield and Sheffield City Council, the facility has become a key facility for the development and research of composite materials, as well as the production of a new generation of carbon fibre tubs.

The first mass-produced carbon fiber components developed and manufactured at MCTC are the active rear wing, rear bumper and front floor for the 765LT.

McLaren Artura (2021)

The mass-produced hybrid super sports car, the McLaren Artura, uses the McLaren Carbon Lightweight Architecture (MCLA), developed and manufactured at MCTC.

To accommodate the new generation of high-performance hybrid powertrains, McLaren has introduced the McLaren Carbon Lightweight Architecture (MCLA) carbon fiber monocoque to the Artura. Lighter and stronger than conventional chassis, the MCLA supports the hybrid powertrain consisting of a 3.0-liter V6 twin-turbocharged engine, further optimizing its structural benefits such as high rigidity levels.

The MCLA is manufactured at the McLaren Composites Technology Centre (MCTC). It not only inherits the lightweight and high rigidity characteristics of the MonoCell and MonoCage II, but also incorporates a safety cell for the hybrid system’s battery, integrating crash and load-bearing capabilities into the tub. The MCLA is also more amenable to mass production than ever before.

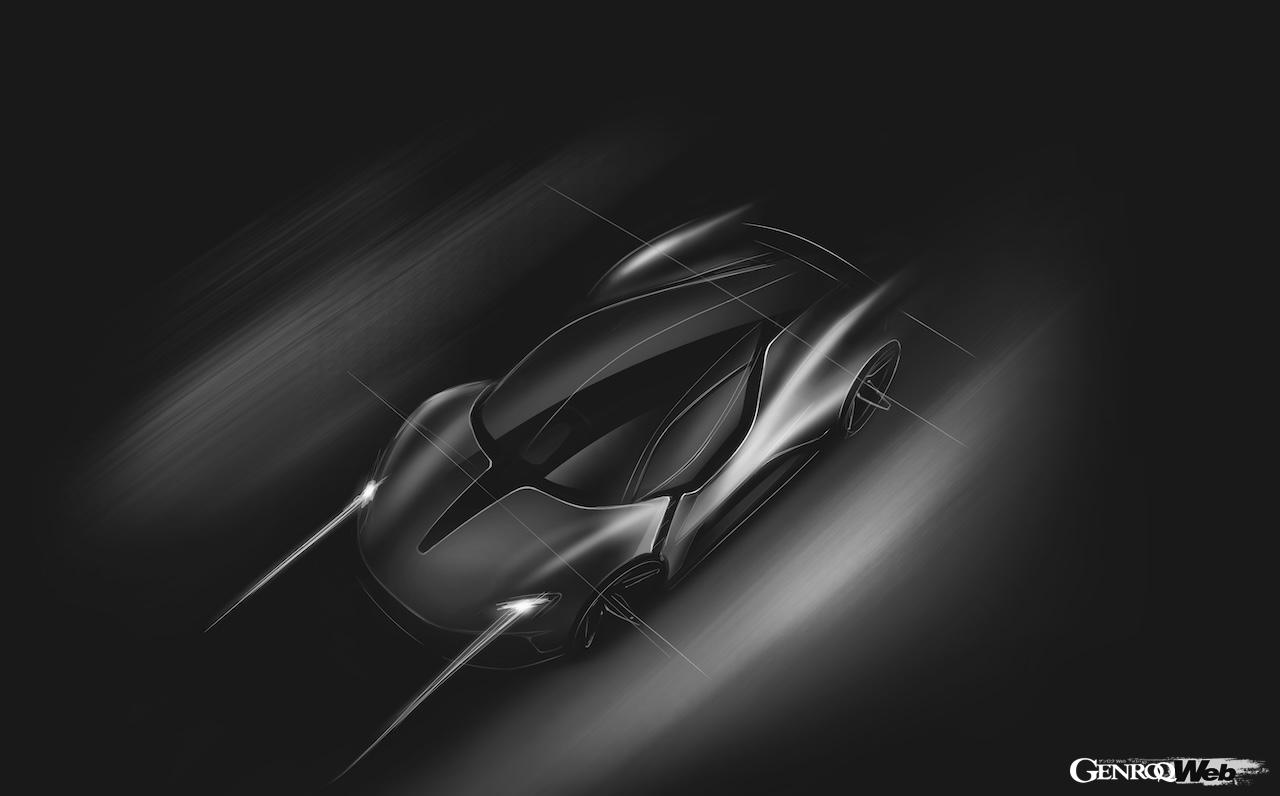

McLaren W1 (2021)

McLaren Automotive’s latest Ultimate Series W1 features Aerocell, the most advanced carbon fiber tub ever fitted to a McLaren road car.

Following on from the McLaren F1 and McLaren P1, the latest addition to the Ultimate Series is the McLaren W1. Continuing the evolution of the company’s lightweight carbon fiber DNA, the W1 features Aerocell, the most technologically advanced carbon fiber tub ever designed for a road car.

Like the track-only Solus GT, it uses pre-preg carbon fiber (an intermediate material made by impregnating carbon fiber with a thermosetting matrix resin). Pre-preg carbon fiber is pressure-treated in a mold, giving the AeroCell greater structural strength than a comparable tub. The AeroCell itself is designed as part of the W1’s aerodynamic package, allowing for efficient use of ground effect.

The W1 also features McLaren’s next-generation carbon fiber technology, McLaren ART (Automated Rapid Tape) carbon fiber. Made possible by the development of high-speed, film-forming manufacturing technology, McLaren ART carbon fiber is lighter, has a higher level of rigidity, and produces significantly less waste. This new technology, which allows for faster manufacturing than conventional methods, is used in the W1’s active front wing.