Porsche Cayenne Electric

Combining real-world testing with digital testing

During the development of the Cayenne Electric, digital testing was actively implemented in addition to traditional real-world driving tests.

Porsche AG is further combining road and digital testing in the development of the new Cayenne Electric, which will be launched at the end of 2025 and sold alongside the current internal combustion engine (ICE) and hybrid models.

“The Cayenne Electric project is the first to move directly from full-vehicle digital testing into pre-production,” explains Michael Steiner, Board Member for Research and Development.

Physical testing using individually built prototypes has now been replaced by digital testing for around 120 test vehicles: instead of time-consuming prototype manufacturing, engineers are sending virtual prototypes out for digital test drives.

Simulation and artificial intelligence (AI) have fundamentally changed vehicle testing, significantly shortening the time required. Digital testing relies on three pillars: precise digitalized driving routes, from the Nürburgring to everyday driving conditions; the experience gained by the engineers in Weissach through many years of real-world testing; and the computing power of modern systems that enable real-time simulations.

These three pillars enabled engineers to not only virtually visualize the Cayenne Electric during development, but also to test it directly in a virtual environment. During the development phase, when each component was first prepared in digital form and could be modified, experts carried out initial tests of the next-generation SUV using virtual reality (VR). The results of these digital tests were later verified in tests using the actual physical components.

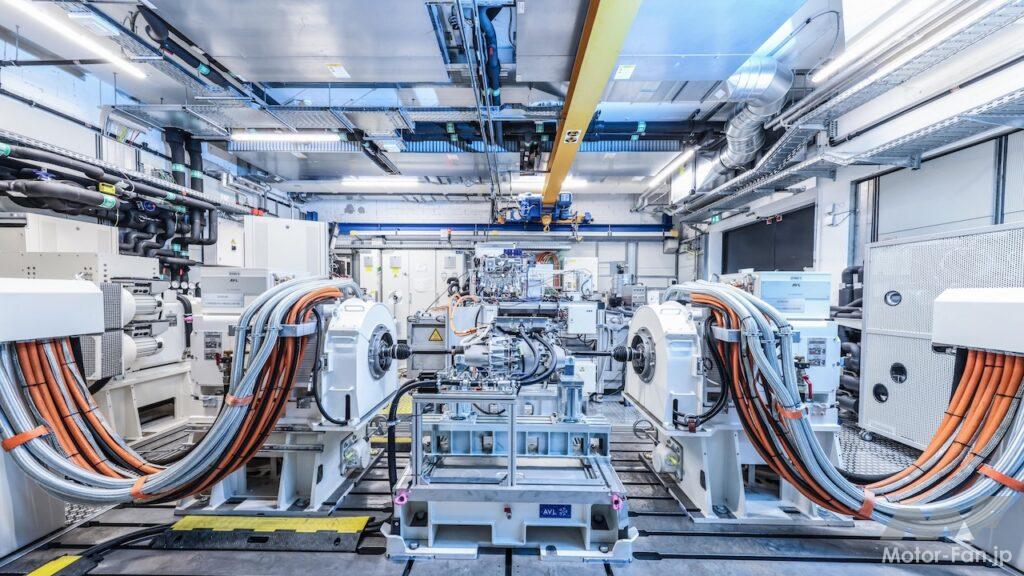

Introducing a newly developed composite test bench

During the development program for the Cayenne Electric, a complex test bench capable of carrying out various simulations was introduced.

The development program for the Cayenne Electric introduced an all-new combined test bench, which makes it possible to test the drivetrain, battery, energy management and charging systems together under realistic conditions.

The four high-power motors installed in the compound test bench can be programmed to accurately reproduce different road conditions, acceleration resistance, and the forces generated during recuperation and braking. “The compound test bench is so sophisticated that it can simulate complete environmental conditions, including different asphalt surfaces and even tire slip,” explains engineer Markus Junige.

“Porsche’s test programme is extremely demanding. The vehicle must always deliver maximum power at the moment the driver requests it, under all conditions,” added Junige.

One example is a lap at the limit on the Nürburgring Nordschleife. Input data was provided by the virtual prototype, and all simulation data was sent in real time to the compound test bench. The production of maximum power puts a great strain on thermal management. To keep the battery in optimal condition in all situations, the heating and cooling systems have been given higher performance than in any fully electric Porsche to date.

Final adjustments left to humans

Although the Cayenne Electric has undergone extensive digital testing, the final tuning and settings are left to an experienced testing team.

No matter how accurate the simulations, the final tweaks are still made by humans: “In reality, only humans can make the finer adjustments,” says Sascha Niesen, team leader for vehicle integrity testing at the Porsche development center in Weissach.

Whether in the city, on the highway or off-road, the Cayenne Electric was tested in a full range of realistic usage scenarios. The test driver’s experience was particularly important on the race track in achieving the perfect balance between driving dynamics and management strategy.

Particular emphasis was placed on charging management: “Regardless of the driving conditions before stopping, the Cayenne Electric is always ready for a quick charge,” says Jünige. The vehicle even takes traffic conditions into account to make the most of the energy stored in it.

Testing in extreme climatic conditions is particularly challenging. In hot climates such as the Middle East and Death Valley in the US, tests were conducted in temperatures reaching 50°C, putting severe strain on the air conditioning system, battery and thermal management of the drive system.

Meanwhile, in Northern Europe, where temperatures can reach minus 35°C, test vehicles are subjected to intensive tests relating to cold starts, climate control, traction, handling, braking behavior and driving dynamics. Under both extreme climatic conditions, the Cayenne Electric had to be able to fast-charge without any problems.

Development time reduced by 20% compared to conventional methods

Although intensive on-road testing is still carried out, the introduction of digital testing has reduced development time by 20%.

The durability tests simulated the vehicle’s lifespan under the harsh conditions that some customers will only experience in extreme circumstances, covering more than 150,000 km over a period of several months and including driving in city traffic, country roads and highways.

From crash labs to endurance driving and testing in extreme environments, the combination of digital and real-world testing has proven its value in every area. Development processes have become more precise and efficient. Compared to traditional development strategies, the development time for the Cayenne Electric was reduced by 20 percent. At the same time, state-of-the-art digital testing is also more resource-efficient, reducing material consumption.